Many industries use polyurethane foam machines for making different products; mattresses are made of comfortable foams while construction uses them for insulation. These Kaiwei foaming machine help in making raw materials to flexible polyurethane products that make the world stand today. The arena of polyurethane foam manufacturing is rapidly changing with technology and environmental concerns, bringing about new ways of doing things that will redefine efficiency, sustainability as well as product versatility.

In the future, the production of polyurethane foam will rely on automation, artificial intelligence and Industry 4.0 practices. The smart factories equipped with IoT connected foam machines shall optimize production lines by allowing real-time monitoring and predictive maintenance. Kaiwei machine foam not only improves productivity but also reduces waste substantially which is in line with the need for circular economies. Additionally, the development of bio-based polyol alternatives aims to reduce reliance on fossil fuels thus increasing sustainability levels in relation to foam.

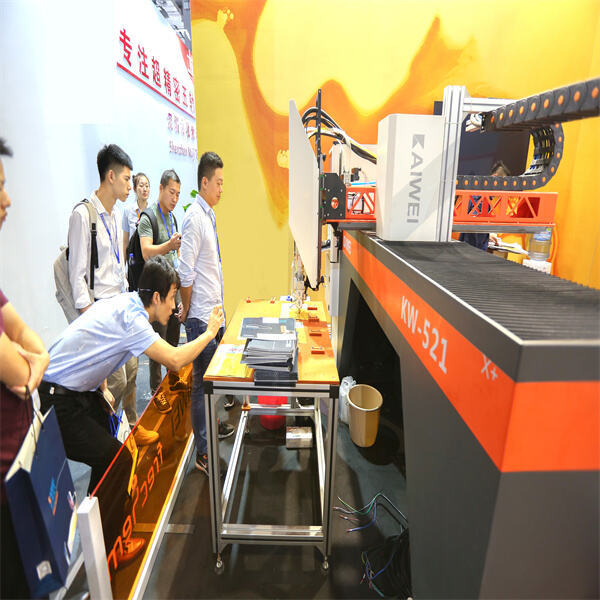

Modern day foam machines have adopted advanced technologies such as precision dosing systems and closed-loop control mechanisms. With these Kaiwei Products one can achieve uniform mix ratios or temperatures hence accurate metering leading to low quality foam that results into decreased scrap rates through automation. Automated mixing heads enable quick formula switches enabling customized production of tailor-made foams for specific customers’ needs. Incorporation of robotics further simplifies this process thereby speeding it up while ensuring accuracy at all costs reducing human error.

To counter global environmental problems, more manufacturers are switching over to eco-friendly polyurethane foam machines. Energy efficient Kaiwei foaming machine consumes less power and produces fewer emissions than traditional ones do; some even have recycling functions which can be used as feedstock in processing scrap or end-of-life foam products. Moreover, water-blown technology has been developed as a substitute for old chemical blowing agents so as to reduce the carbon emissions related with foam products without affecting their performance levels.

The versatility of polyurethane foam machinery has made it usable in many industry sectors. Kaiwei machine foam is used in making lighter but long-lasting automotive parts that increase efficiency in fuel consumption. This means that it can also be employed in insulation within construction whereby it provides great thermal resistance and sound reduction. For example, cushioning is found in prosthetic devices while specialized foams are used on hospital beds to prevent pressure injuries from occurring. In sports and leisure activities, such as helmets or athletic shoes, comfort and safety are enhanced by polyurethane foams.

KW-900 hybrid head has Patents national inventions. No measurements of raw materials, and no pressure controls (no frequently measured raw material density because weather conditions throughout the years). The amounts of the size of glue spits, the systems screen parameters can be adjusted at any time, exact glue. The raw materials are not changed, the amounts of raw materials not altered, and the Polyurethane foam machine shall be manually weighed prior to each use. No requirements to have a room with air conditioning.

For Polyurethane foam machine that has foams sealing pad can reach IP67 or even greater. And we also have CE certificate. Kaiwei fully automatic foam sealing machines equipped with three axes, eight servo motors, 8 reducers four metering pumps.

There is no need for a professional operation Reduces the load on workers. It is Polyurethane foam machine. Newcomers can start in only 30 minutes.

We provides comprehensive after-sales services on-site, and an Polyurethane foam machine that increases customer satisfaction. When it comes to equipment troubleshooting or maintenance needs, or even training needs we'll promptly schedules personnel to be on site to resolve the issues in a timely manner to assure the smooth production and performances of our customers.

Foam manufacturing is a process that needs strict quality control; therefore modern day machines have come up with sensors and analytics software which are very complex. The inline density measurement systems will ensure consistent product consistency whereas infrared cameras monitors curing processes ensuring they work under optimum conditions all the time. With advanced data analytics, manufacturers can predict quality problems thus allowing early addressing of such issues before they occur. The precision involved helps to endow every batch with the desired quality standards thereby building confidence among consumers who rely heavily upon these materials while shopping at markets today.

To conclude, polyurethane foam machines are leading in creating innovations that are advancing the manufacturing efficiency, sustainability and product variety. But as technology advances so does that of Kaiwei Products, it is shaping a future where polyurethane foam products will not only be high performing but also have an environmental consciousness and economic efficiency. The most exciting time for this industry is now when it starts to surpass current limits of what can be achieved by polyurethane foam.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog