PU potting machine for KW-520CL Automatic foam Sealing machine with two-component polyurethane raw materials

- Overview

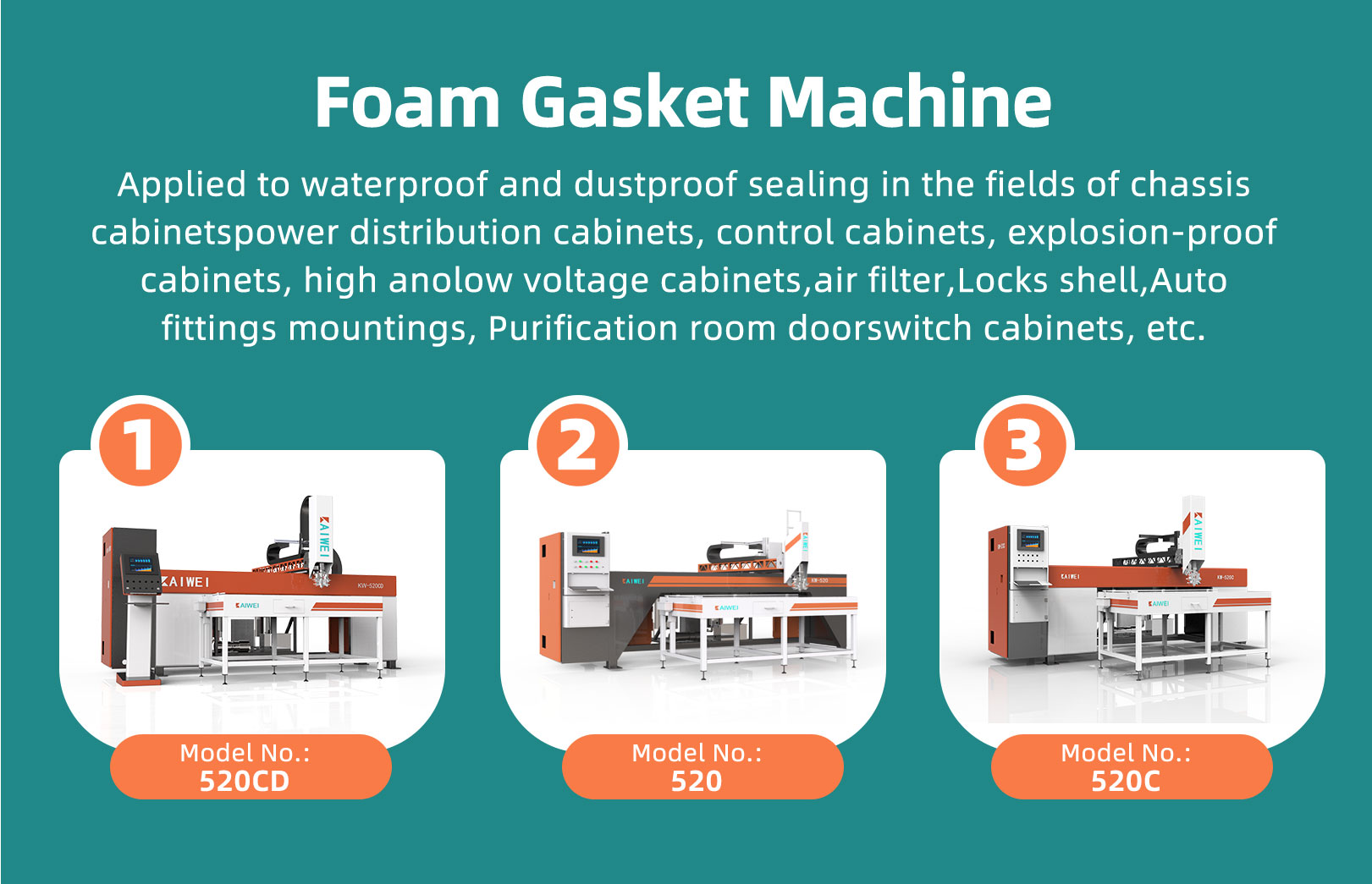

- Recommended Products

Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. was founded in 2004 and headquartered in Shanghai. As a high-tech enterprise, Kaiwei specialized in R & D and production of industrial sealing system and robot foaming equipment. The company has professional R & D institutions, perfect technical innovation system, and provides automation electrical solutions for well-known enterprises at home and abroad.

Q1: Are you a factory or trading Company?We are a professional machines manufacturer. Our headquarter is in Qingpu district, Shanghai, CN. Our factory located in Suzhou district, Jiangsu, CN. It only takes 30 mins from Hongqiao airport/train station to our headquarter, you are always welcome to visit us.

Our engineers are also available to serve on abroad.

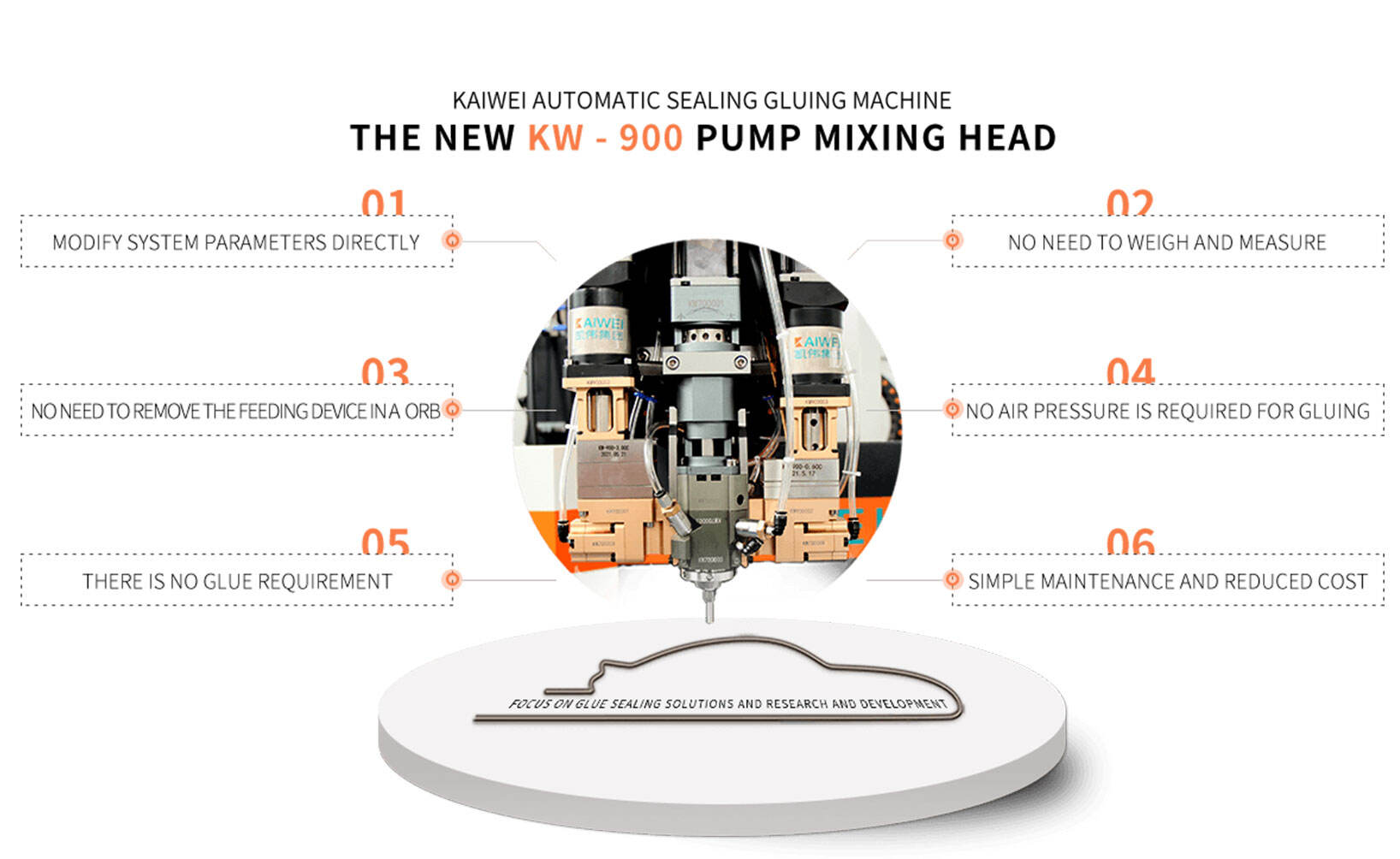

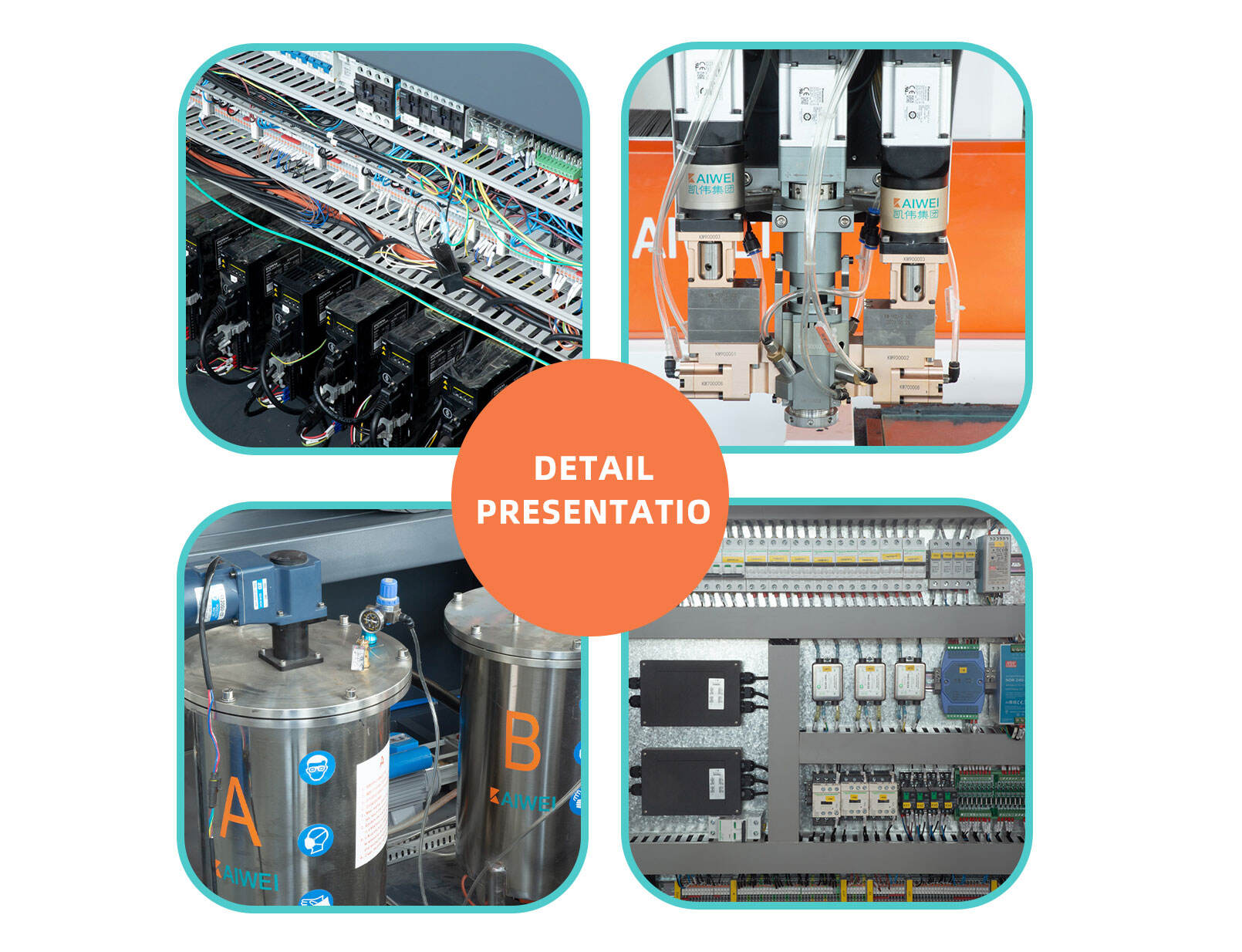

Introducing the PU potting device for KW-520CL Automated foam Securing device along with two-component polyurethane basic materials through Kaiwei - your service best for and procedures that are bonding. This equipment greater degree anybody towards help polyurethane two-component, that makes it appropriate for lots of bonding requests and securing. The PU potting gadget was produced towards run perfectly due to the KW-520CL foam securing device, offering you along with an instead effective and treatment precise. Along with the enhancement of the PU potting gadget, it is feasible towards you have to get your securing and bonding capability towards degrees that might be new complying with its own functions that are numerous advantages.

Among lots of main advantages of the PU potting device for KW-520CL Automated foam Securing device along with two-component polyurethane basic materials is its own ability towards procedure polyurethane products that are two-component. This provides one towards achieve an excellent, resilient and connection enduring will endure severe environmental problems, consisting of severe problems, moisture, and promotion chemical. Likewise, the PU potting gadget enables you towards minimize squander through correctly dispensing the quantity appropriate of along with every duration. The PU potting device for KW-520CL Automated foam Securing device along with two-component polyurethane basic materials includes higher degree innovation that allows anybody towards produce bonding and securing items easily and solutions.

It includes a request easy to use assist you towards change the setups previous for your demands. Additionally, the equipment is totally automated, for that reason you might obtain results which is frequently high-quality having to intervene by hand. The PU potting device for KW-520CL Automated foam Securing device along with two-component polyurethane basic materials is created along with high-quality products, ensuring it will withstand for a lengthy quantity of your time in the long-term.

It is typically created towards require maintenance very little exercising for you maintain your operating sets you back reduced. You will count on the PU potting gadget towards provide continuous, reliable efficiency each time you use it.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ