In many industries including electronic, automotive and medical equipment production a dispensing sealing machine is an important tool that enables precise fluid dosing. Needle debugging methods by Kaiwei are essential to efficiency and accuracy in the dispensing process read more about the benefits of using needle debugging techniques, what technology is used and how safe it is to use, the right way on how you can needle debugging, its applications in varied industries.

Advantages:

Needle debugging method is comparatively very efficient than the traditional methods. This also provides the important quality of identifying with all types of flaws that could result in leaks or blockages during dispensing. In this way, the companies not only save on time and money but also spot and fix defects during dispensing which helps improve their overall product quality as well lesser production wastes or reworks.

Development:

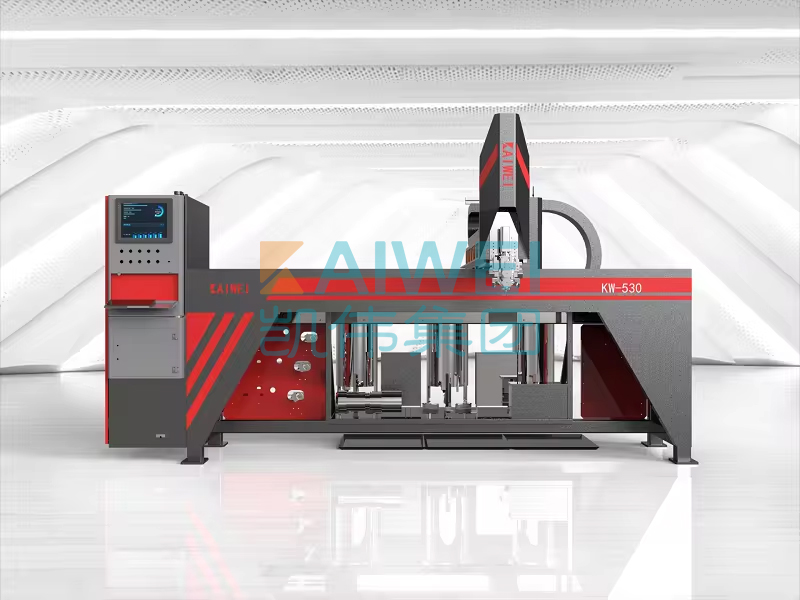

Needle Debugging is a more sophisticated technique that relies on high resolution cameras, sensors and software but we will save this quickest way for another post. These are precision devices like Auto Foam Sealing Machine that allow the manufacturer to identify and analyze even these very small defects in the needle, opening what we think is a significant amount of useful data that can be used to optimize dosing and quality for new levels.

Safety:

Using a sealing device for dispensing tweety require to ensure workplace safety in the first place. This helps in preventing any errors associated with the needles and limits the exposure to potential accidents during use. This way of working should lead manufacturers to build a safe space for their employees, where they trust in the safety and wellbeing culture.

How to Use:

The needle debugging technique is so simple, and easy to implement with. Firstly, the needles are prepared and sterilized pretty comprehensively for tests. Afterwards, they are placed under a high resolution camera for failure detection. This data is then analyzed with the help of an application software to recognize any discrepancies if there are any. Ultimately, the needles are tweaked and tested once again to confirm that they perform as required.

Maintenance:

With maintenance and servicing the efficiency of needle debugging can be maintained. This involves something like cleaning the needles, changing worn parts and if necessary updating software. Manufacturers can continuously prevent potential problems and keep the sealing dispensing process reliable by following a uniform servicing routine.

Quality:

Needle debugging is a reliable step to ensure the quality of dispensing. Manufacturers who identify defects quickly, and address them before they become a real problem, are better able to reduce waste and improve the overall quality of their goods or machine over time this leads to happier customers.

Application:

A very common observing method in industries like electronics, automotive and medical equipment production is Needle debugging. This extreme accuracy is most clear in use cases that require exactness such as the healthcare industry where accurate dispensing of drugs and surgical products must be guaranteed to maintain patient health/safety.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ