Industrial foaming machines form a cornerstone in the production processes of many industries such as automotive, construction as well furniture and packaging. It is by means of these sophisticated systems that various foam products, like insulation and cushioning with protection wrapping are made from taw materials. Given the progressive nature of technology, industrial foaming machines are evolving with more efficiency and flexibility to respond to precision, cost performance demands as well as environmental awareness. Here, in this elaborate article on the latest innovation and technology, money saving attribute improvement of eco-friendly machines to selection standards as well as its extensive application capabilities provide a deeper insight.

Right now the industrial foaming landscape is experiencing what some consider rapid technological changes. It features IoT (Internet of Things) and Industry 4.0 principles implemented in the machines to facilitate remote monitoring, predictive maintenance, as well supporting real-time adjustments for the highest quality foam across all production types. Furthermore, the use of smart metering ensures recording and monitoring based on-shell percentage giving accurate ratios to manufacture a sustainable product reducing any waste. Moreover, the latest machines will be better at conserving energy through the use of Variable Frequency Drives that make them more energy-efficient and help in maintaining a consistent process control. Advances such as 3D foam printing technologies have enabled the manufacture of intricate part geometries, and customization in a way that was never before possible with molded foams.

What to keep in view is that efficiency counts a lot when it comes reducing cost and increasing the productivity of manufacturing sector. These features are fulfilled in the modern setup utilizing industrial foaming machines where many of these functions are automated reducing considerably manual labor and hence human errors. This ensures accurate doses are used which also saves on material waste and improves yield, as automated mixing and dispensing replace manual measuring. Fast production, on the other hand, is a high-speed line which allows for large volume in shorter durations resulting into higher throughput. Energy savings of up to 70% are a direct result of careful incorporation and energy-efficient design, etc. (insulated tanks), residual heat recovery systems components at hand! Industrial foaming machines are pivotal in the reduction of operational costs through process optimizations and resource utilization gains which improve yield efficiency.

The constant factor which motivates the development of industrial foaming machines is sustainability. In recent years, companies have developed machines for the aforementioned Hilux BIODEGRADABLE and GROEN (recycled foam) materials so environmentally conscious manufacturers can decrease their carbon footprint. More complex recycling processes can sometimes be found in these systems, so that parts scraps produced during manufacturing and disposed of are minimized. Use of water based blowing agents replaces traditional chemical alternatives and greatly reduces greenhouse gas emissions. In addition, energy-efficient machines designed wear regenerative drive systems can contribute to larger carbon footprints. These technologies are green in nature which brings the businesses to par with global sustainability goals and at same time these broaden up environmentally friendly image of brands.

Choosing the appropriate industrial foam machine requires a comprehensive assessment of these considerations. This means you should be able to identify your production output (how much, what kind of products and also the foam requirement) because that will help determine how big or small a machine is required. Material compatibility - The foam formulation you plan to use and the machine are made for each other. Essentially, you need to balance that with the long-term savings obtained when looking at energy efficiency and operational costs. In addition, deciding the appropriate extent of automation for your operations (weighing capital expenditures against productivity improvements) is critical. Great care should be paid to post-purchase support, including maintenance services and technical assistance in order to allow the continued operation of businesses. Finally, when you are investing it is important to ability to future-proof that investment by ensuring the machine can integrate with new technologies and meet evolving market demands.

It is not necessary to have a professional operating industrial foaming machine. Simple to use. Beginners can begin in just 30 minutes.

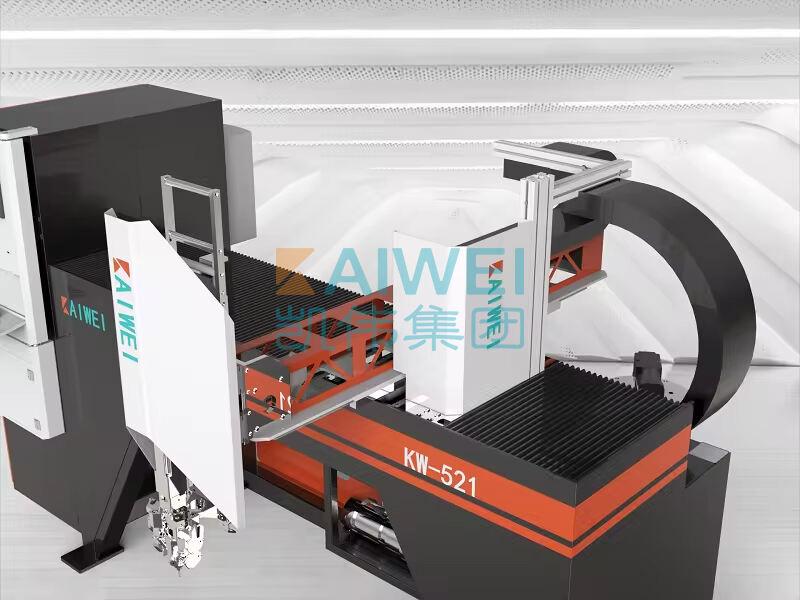

The KW-900 hybrids heads are protected by the benefit of a patent that national. The heads do not measure raw materials is required and no pressures control needed (climate conditions throughout the year prevents frequent measurements of raw density materials). Modify the screen parameters, industrial foaming machine, quantity of glue spit. to suit your needs.

In the protections level test the industrial foaming machine can be IP67 or even more. And we also have CE certificate. Kaiwei fully automated foams sealing machines adopts three axes, eight servo motors, 8 reducers and 4 meters.

Our company is industrial foaming machine as well as an innovative online educational apps to enhance customer satisfaction and experience. We'll sends employees to the site for training, maintenance or troubleshooting to solve the issues in a prompt way. This will ensure that our customers are able to continue operating and continue to produces as normal.

This widespread use across industries highlights the versatility of industrial foaming machines. In the automotive sector, meanwhile, they are used for producing seat cushions and impact-absorbing components in addition to acoustic insulation. In the construction industry, industrial foaming machines are used for making insulation boards and roofing membranes as well as sealants which help in saving energy by increasing efficiency of buildings. Foam machines are used by furniture manufacturers for upholstery padding, mattresses and cushions, to ensure the perfect balance between comfort allowing maximum utilization life of their products. Foam (used for protective inserts, molded trays and insulation materials) is used widely in the packaging industry to aid safe transportation of fragile items. In the case of medical devices, sports equipment and footwear for instance, industrial foaming allows manufacturers to produce higher performing goods according to certain performance needs. This broad application background is a clear indication of why industrial foaming machines are essential in the contemporary manufacturing world.

This article is concluding here, and I hope it has provided you with an idea on to how industrials foaming machines 1re playing a part in the innovation field for providing a combination of efficiency combined with sustainability & flexibility. As one story changes another, the strategic choice of appropriate machinery play on the competitiveness and environmental role in industries. Manufacturers can thus access new paths to growth and mastery in their fields by leveraging innovative technologies as well as incredibly selective mechanisms.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog